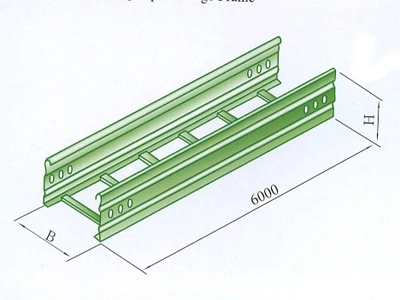

1. Cable ladder

The CQ1-T type stepped cable tray is improved and designed based on relevant domestic and foreign data. It has the advantages of light weight, low cost, unique shape, easy installation, heat dissipation, and good ventilation. It is suitable for the laying of generally larger diameter cables and suitable for the laying of high and low voltage power cables.

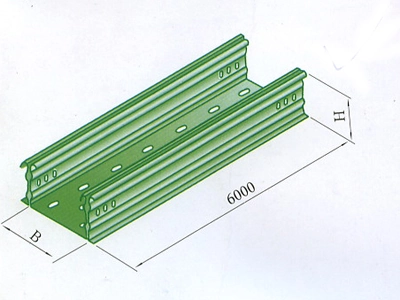

2. Tray type cable tray

Tray type cable tray is the most widely used in petroleum, chemical industry, light industry, telecommunications and other fields. It has the advantages of light weight, large load, beautiful appearance, simple structure and easy installation. It is suitable for both the installation of power cables and the laying of control cables.

3. Trough type cable tray

The trough cable tray is a fully enclosed cable tray. It is most suitable for laying computer cables, communication cables, thermocouple cables and other control cables for highly sensitive systems. It has a good effect on shielding interference of control cables and protecting cables in heavy corrosion environments.

The ladder type, tray type and trough type cable trays have their own advantages and disadvantages: the ladder type cable tray has good ventilation performance, but is not dustproof or interference-proof. Trough-type and tray-type cable junction bridges have dust-proof and anti-interference properties.

4. Large span cable tray

Currently, large-span cable trays are generally assembled from pultruded fiberglass profiles and are suitable for power cables, control cables, lighting cables and accessories. Compared with iron bridges, it has a long service life (generally designed life is twenty years), easy installation and low cost (the specific gravity is only 1/4 of carbon steel, no fire is required during construction, and the length of a single bridge can reach 8 meters, or even longer), easy cutting, and no maintenance required.

5. Combined cable tray

The combined cable tray is a new type of bridge and the second generation product in the cable tray series. It is suitable for various projects, various units, and the laying of various cables. It has the characteristics of simple structure, flexible configuration, convenient installation, and novel form.

The combined cable tray only needs to use three basic types with a width of 100, 150, and 200mm to form a cable tray of the size you need. It does not need to produce bends, tees and other accessories, and can be arbitrarily turned, widened, or changed according to on-site installation. Lead up and down. It can be led out by pipe at any position without drilling or welding. It not only facilitates engineering design, production and transportation, but also facilitates installation and construction. It is the most ideal product among cable trays.