The cable tray can be divided into Wire Mesh Cable Tray, Cable Ladder, Enclosed Cable Tray ,Perforated Cable Tray and so on. A structural system with a certain rigidity.

The bridge frame in the building can be erected independently or attached to various buildings (structures) and pipe gallery supports. It should reflect the characteristics of simple structure, beautiful appearance, flexible configuration and convenient maintenance. All parts need to be galvanized. , installed in the open air bridge outside the building. A rigid structure system with close-connected supporting cables is composed of trough, tray or stepped straight sections, bends, tee, four-way components, brackets (arm brackets), hangers, etc. ).

1.Wire Mesh Cable Tray

The structure of the grid bridge is similar to the mesh, hence the name grid bridge.

The wire mesh cable tray is mainly used in the construction of the computer room, which plays a vital role in the protection of cables in the construction of the modern computer room, greatly reduces the cost and energy consumption, and is an indispensable wiring device for the comprehensive wiring of the computer room.

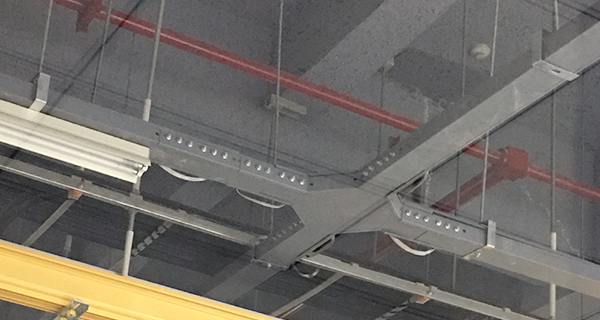

2.Ladder cable tray

Trapezoidal cable tray is the abbreviation for the component that directly supports the cable. It is a trapezoidal component composed of two longitudinal sides and several rungs.

CQ1-T type stepped cable tray is improved and designed according to relevant domestic and foreign materials. It has the advantages of light weight, low cost, unique shape, convenient installation, good heat dissipation and good ventilation. It is suitable for the laying of cables with larger diameters in general, and for the laying of high and low voltage power cables.

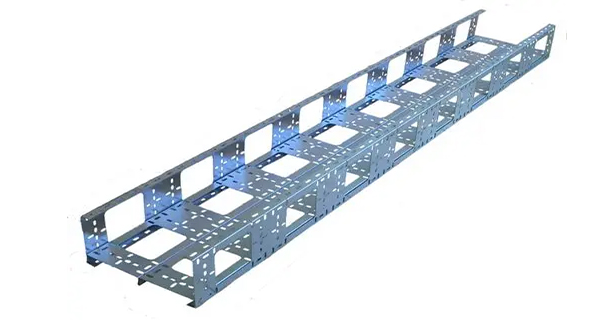

3.Perforated Cable Tray

There are two types of tray-type cable trays

1. Tray with holes: the abbreviation of the component that directly supports the cable of the slotted cable tray with holes, which is composed of a bottom plate and sides with holes or a slot with holes at the bottom formed by punching a whole aluminum alloy plate and then bending it. shaped parts.

2. Non-porous tray: short for the component that directly supports the cable of the non-porous slot-shaped cable tray, which is composed of the bottom plate and the side or a solid-bottom slot-shaped component formed by bending a whole aluminum alloy plate.

Tray-type cable tray is the most widely used in petroleum, chemical, light industry, telecommunications and other fields. It has the advantages of light weight, large load, beautiful appearance, simple structure and convenient installation. It is suitable for both the installation of power cables and the laying of control cables.

4、Trough cable tray

The trough cable tray is a fully enclosed cable tray. It is most suitable for laying computer cables, communication cables, thermocouple cables and control cables of other highly sensitive systems.It has a good effect on the shielding interference of control cables and the protection of environmental cables in heavy corrosion.

The advantages and disadvantages of the stepped cable tray, the tray type and the grooved cable tray: the stepped bus cable tray has good ventilation performance, and is not dustproof or interference-proof. Slot-type and tray-type bus bridges have dust-proof and anti-interference performance.

五、Large span cable tray

At present, long-span cable trays are generally assembled from pultruded FRP profiles.

Large-span cable trays are generally suitable for power cables, control cables, lighting cables and accessories. Compared with the iron bridge, it has a long service life (general design life is 20 years), easy installation and low cost (the specific gravity is only 1/4 of carbon steel, no hot work is required during construction, and the length of a single bridge can reach 8 meters, even longer), convenient cutting, no maintenance and other advantages.

六、Combined cable tray

The combined cable tray is a new type of cable tray, which is the second generation of the cable tray series. It is suitable for the laying of various projects, various units and various cables. It has the advantages of simple structure, flexible configuration, convenient installation, Features such as novelty.

As long as the combined cable tray adopts three basic types of width 100, 150, and 200mm, it can form the cable tray of the size you need. It can be arbitrarily turned, widened, Divide up and down. In any part, it can be led out by pipe without punching or welding. It is not only convenient for engineering design, but also convenient for production and transportation, and more convenient for installation and construction. It is the most ideal product in the cable tray.